Cylinder gases are very important in different industrial applications where efficiency and accuracy in the processes of manufacturing, healthcare and many other activities are required. As industries and companies adopt more gas solutions, it is important to be knowledgeable of the different types of gases, their application, and the cylinder gas safety guidelines.

What is A Cylinder Gas?

Cylinder gas is defined as a gas which is packed and maintained in high pressure cylinders for industrial or medical applications. These can be compressed gases or liquefied gases and even cryogenic in form and these gases find usage in different applications such welding, cutting, medical purposes, and even in food preservation.

Being one of the top cylinder gas suppliers, HCM has several cylinder gases for different industries. Whether it is industrial nitrogen or oxygen for medical Wil have to comprehend what for the gas is going to be used.

Types of Cylinder Gas and Their Applications

Cylinder gases are important in different industries and are stored in various cylinders. Some of the most popularly utilized cylinder gases comprise the following:

Oxygen (O2)

Cylinders containing oxygen are primarily industrial gases reliable for medical use. Other usages include welding, metal cutting, and glass manufacture. By assisting in combustion, oxygen allows greater levels of heat and energy during welding or cutting operations.

Nitrogen (N2)

N2 gas has other applications including food preservation as it replaces O2 to slow down oxidation and deterioration. Such gas is also critical in the electronics industry to provide inert environments during several manufacturing stages, including semiconductors production.

Carbon Dioxide (CO2)

Carbon dioxide is primarily used in the foods and beverages industry in the preparation of carbonated soft drinks and beer. Apart from these, it is also utilized in manufacturing fire extinguishers and in welding operations in particular MIG welding.

Argon (Ar)

Argon is a noble gas commonly employed in various types of welding, particularly when a stable, inert atmosphere is needed. Argon is commonly employed in the production of light bulbs and electronics.

Acetylene (C2H2)

Acetylene is one of the flammable gases used in welding and cutting metals. It’s flame is very hot and therefore can be used for various purposes such as brazing and soldering.

Safety Precautions while Utilizing Cylinder Gas

The cylinder gas can be used in a safe manner as long as safe usage, proper handling and storage is guaranteed. The safety regulations are very clear and prominent

.

Store gases at the recommended location: Make sure that gas cylinders are kept upright and in a location that is away from anything hot or flammable.

Conduct leak testing: Cylinders should be checked for leak detection prior to use. Gas leakage is dangerous especially for flammable and reactive gases.

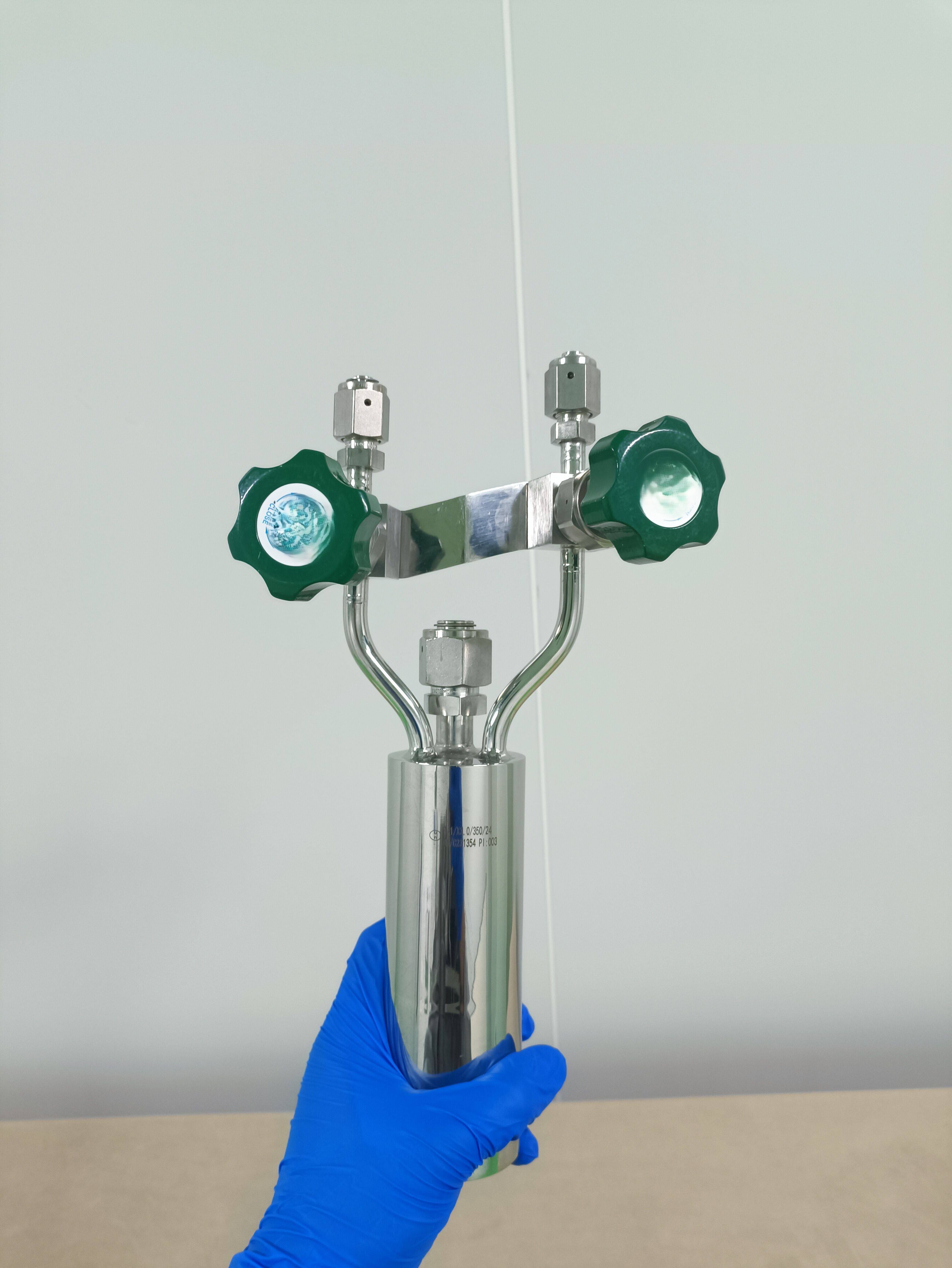

Install suitable regulators and fittings: In order to avoid accidents caused by incompatible fittings, always use appropriate regulators that are made for the gas in use.

Safely fasten cylinders: Care should be taken that cylinders are securely fastened to avoid accidental tipping over which may cause a leak or an accident.

Utilize protective equipment: Bear in mind to utilize the relevant protective gear such as gloves, goggles, or even flame-resistant clothing depending on the type of the cylinder gas being used.

We understand the risks. That’s why we deliver safe experiences by ensuring the provision of high quality cylinder gases and supporting industries with proper safety details.

Cylinder gases have always been one of the basic requirements for various industrial and medical processes. It could be oxygen in a hospital, nitrogen in an industry, or carbon dioxide in food packaging. For every application, the right gas needs to be selected and used with care. Due to the broad spectrum of cylinder gases offered by HCM, industries are able to work effectively and securely, with all sorts of clear explanations and detailed recommendations.